Through an independent study in collaboration with my composites manufacturing course, I designed, tested, and manufactured a prototype carbon fiber skateboard.

The Initial Design Phase was completed by testing the properties of different manufacturing processes and materials. The 5 separate samples tested included these variables:

- Manufacturing through Vacuum and pressure Only for 24 hours

- Manufacturing through heat treatment and vacuum for 24 hours

- Layering Prepreg carbon fiber and heat treating*

- Layering Carbon Fiber with fibers in one direction*

- Layering Carbon fiber with fibers in alternating directions*

*Samples manufactured using vacuum and heat due to results of previous tests

Testing of the Samples included:

- Stress-strain calculations

- Tensile Testing

- 3-point bend test

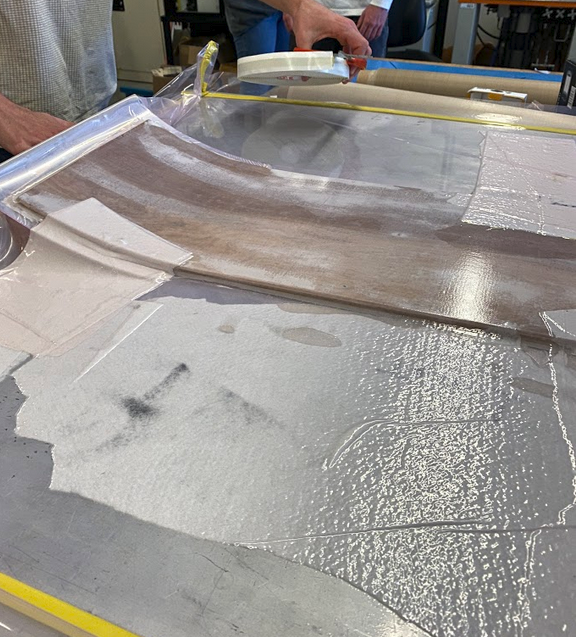

After the initial design phase was complete, I prototyped 2 different designs. The final result included an aerodynamic surfboard shape with a plywood base layered with 2 layers of fiber glass composite and 8 layers of carbon fiber composite cured with vacuum seal and a heat treatment. The board was then cut to shape utilizing various power tools to ensure accurate cuts. The final 3 point bend test on the board was inconclusive as it did not break under the Instatrons maximum force and thus it could not be concluded it's true Young's Modulus or Ultimate Stress.